Understanding Fluid Power

by kind permission of Erik Lanke, President of NFPA.

What is Power Transmission?

Standard electric motors typically rotate at 1,000 or 3,000 revolutions per minute (synchronous no-load speed – rpm) – much faster than is practical for most machines. Internal combustion engines also rotate at thousands of rpm when powering equipment. Some form of power transmission, therefore, is needed to convert power from the motor or engine to a more useable form – slower speed and often, linear motion instead of rotary.

Mechanical power transmission methods include gear, chain, belt and other mechanical drives that convert the high-speed mechanical power from the engine or motor’s output shaft to a slower speed with higher torque (twisting force). Mechanical power transmission components also include ball screws, rack and pinion assemblies, chain drives, and other components that convert rotational motion and torque to linear motion and force.

Electrical methods of power transmission regulate electrical power to the motor to control speed and torque. These methods cannot convert the rotary motion of a motor to linear. When linear output is needed a linear motor may be used, but its high cost generally makes a mechanical rotary-to-linear motion device more practical for producing linear motion and force.

In many cases, however, mechanical and electrical methods cannot provide a practical power transmission solution. In these cases, fluid power – whether hydraulic or pneumatics – is used because it can deliver linear and rotary motion with high force and torque within a smaller, lighter package than is possible with other forms of power transmission

A cement mixer, for example, illustrates how different methods of power transmission may be used. Early cement mixers used mechanical drives driven by the truck’s engine or transmission. A system of gears, chain drives and drive shafts provided the speed and torque necessary to rotate the heavy drum of concrete, but speed was difficult to control. The rotational speed of the drum depends upon the engine or transmission speed. As the driver changes gear, the drum would speed up or slow down and rarely rotated at the desired speed. In addition, the complexity and bulk of all the mechanical components were highly maintenance intensive.

An electrical drive could provide good speed control but would require a high-power electric generator, controls and a motor to drive the drum. The motor would be prohibitively large or would require a large gearbox to achieve the low rotational speed of the mixer drum. Either solution would result in a much larger and heavier installation than a hydraulic drive.

Hydraulic drives are the primary choice for cement mixer drives. They use a pump, hydraulic motor and valves to control speed regardless of the engine or transmission speed. The drum rotates at optimum speed, or maybe controlled manually. The components are relatively compact with the pump tucked away within the framework of the truck and the hydraulic motor is only a small fraction of the size of a comparable electric motor gearbox combination.

What is Fluid power?

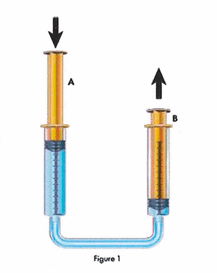

Fluid power is a term describing hydraulics and pneumatics technologies. Both technologies use a fluid (liquid or gas) to transmit power from one location to another.

With hydraulics the fluid is a liquid (usually oil but can be water) whereas pneumatics uses a gas (usually compressed air). Both are forms of power transmission, which is the technology of converting power to a more useable form and distributing it to where it is required. The common methods of power transmission are electrical, mechanical and fluid power, although they are sometimes viewed as competing technologies, no single method of power transmission is the best choice for all applications. In fact, most applications are served by a combination of technologies. Fluid power, however, offers important advantages over the other technologies.

Fluid power systems easily produce linear motion using hydraulic or pneumatic cylinders, whereas electrical and mechanical methods usually must use a mechanical device to convert rotational motion to linear. Fluid power systems generally can transmit equivalent power within a much smaller space than mechanical or electrical drives, especially when extremely high force or torque is required. Fluid power systems also offer simple and effective control of direction, speed, force and torque using simple control valves and can be integrated with sophisticated electronics for more precise control. Fluid power systems often do not require electrical power, which eliminates the risk of electrical shock, sparks, fire and explosions.