Members’ News

28 Sep 2020

FPE seals announces new Managing Director

FPE Seals, BFPDA member and worldwide distributor and manufacturer of polymeric seals and hydraulic cylinder parts, has appointed Steve Ellis as its new managing director.

FPE Seals, BFPDA member and worldwide distributor and manufacturer of polymeric seals and hydraulic cylinder parts, has appointed Steve Ellis as its new managing director.

Steve assumes the role following the recent retirement of Nick Davies after four successful years at FPE. Steve joined FPE Seals in June, coming from the LoneStar Group, a global manufacturer and distributor of high-performance fasteners, sealing products and precision engineered components to the world’s energy markets. Steve was responsible for Group Purchasing at LoneStar before moving to Ningbo, China as Managing Director of LoneStar PHIT and, most recently, Houston, Texas where he was Managing Director of LoneStar Fasteners and LoneStar Sealing Technologies.

FPE Seals provide marketing-leading products to meet the urgent needs of engineers, repairers and resellers internationally, operating from branches across the UK, including Swan Seals in Aberdeen, as well as Breda, in The Netherlands. The company is part of Diploma PLC, a FTSE 250 international group of businesses supplying specialised technical products and services.

Commenting on the appointment, Alessandro Lala, CEO International Seals at Diploma PLC said, “We are delighted to welcome Steve to the Group, he brings with him a wealth of leadership and procurement experience and his appointment will ensure that we have a strong team to facilitate our continued growth.

“It is strange time for anyone to be joining a business however, I am happy to say that the COVID-19 emergency has only proven the resilience of our business model, continuing to provide essential products to a variety of markets, strengthening the loyalty of our customer base.

“I would also like to thank Nick Davies for his incredible contribution to the company during the four years he spent with the business, and who did an excellent job of navigating FPE through recent months, ensuring safe working conditions for his colleagues and managing the business through difficult circumstances. I wish him the very best for the future.”

Steve added, “I am honoured be to be leading FPE Seals into the next stage of its future growth. I look forward to working with the team and developing new solutions that will bring added value and satisfaction for our customers”.

Moog helps researchers build a better turbine blade test

BFPA member Moog, designer and manufacturer of high-performance motion control products and solutions, has applied its expertise with servo control and actuation to help create a testing facility for researchers at the Technical University of Denmark (DTU) Large Scale Facility, part of the Department of Wind Energy and the Villum Center for Advanced Structural and Material Testing (CASMaT).

BFPA member Moog, designer and manufacturer of high-performance motion control products and solutions, has applied its expertise with servo control and actuation to help create a testing facility for researchers at the Technical University of Denmark (DTU) Large Scale Facility, part of the Department of Wind Energy and the Villum Center for Advanced Structural and Material Testing (CASMaT).

Underpinning the test facility on the DTU Risø campus in Denmark, is Moog’s digital closed loop control system and application software. Moog and its partner T A Savery (also a BFPA member) designed and installed test equipment for three test stands, which can accommodate 15-, 25- and 45-meter wind turbine blades. Moog engineers carried out the installation and commissioning of the test equipment. Moog also is providing ongoing support to the DTU staff. The Moog scope of supply for the three blade test stands included: the hydraulic power plant and distribution network’ six hydraulic winches for the static testing; and a combination of eight mass resonance exciters (MRE) and linear actuator assemblies for dynamic test work. In addition the project also included all pipe work, hosing and actuation devices, control system electronics, and application software. To design the winch assemblies, Moog collaborated with U.K.-based Qualter Hall, a provider of bespoke hoisting, winching and haulage systems.

“Much analysis went into how the MRE would work, the frequency and how DTU would like it to perform,” adds Graham Wood, Managing Director with T A Savery, a U.K.-based firm with a 200-year pedigree of engineering and machining for industries ranging from defence to mining and a long-standing relationship with Moog. “This was not a contract in which the customer simply said, ‘Make A, B and C and that’s that.’ Moog won the contract, and then began a great deal of technical research, modelling and hardware design.”

Moog’s goal was to give DTU the latitude to conduct an array of tests. For example, if researchers wanted to use a test bay to conduct a dynamic test on a blade, the hydraulic system would accommodate wide pressure fluctuations. If the next test required a static one with winches, DTU could set the hydraulics to meet a very-low flow.

“DTU can select what they want, without being constrained by the equipment,” adds Kevin Cherrett, business segment manager for Systems and Services with Moog’s Industrial Solutions & Services Group.

Moog continues to support DTU’s work via a project in which researchers hope to increase the reliability of wind turbine blades.

“Moog’s technology is helping with this because we will embed sensors in test blades with built-in defects and monitor how the damage grows, whilst the Moog exciters will put realistic loads on the blades,” says Dr. Kim Branner, senior research scientist and head of the Structural Design & Testing Team for DTU Wind Energy.

Meanwhile, Branner sees the project helping blade makers build better blades but also creating a digitised twin of each blade that a wind farm operator can use to model what a blade’s future state might look like. If all goes according to plan, sometime soon, a wind farm control centre will be able to predict blade failure before it happens.

For more details about this project, including a video please visit:

http://info.moog.co.uk/bladetest7

NFPC Recommends the BFPA Minimum Education Recommendations (MERs)

In its strive to continue to support the knowledge and skills development of the UK workforce, the NFPC has developed a range of ZOOM based Webinars and follow-on practical training days fully embracing the BFPA (MERs). These are available relating to Hydraulics, Pneumatics and Applied Electronics and delivered by NFPC Systems Training Engineers with a vast knowledge and experience to compliment the delivery process.

With Webinar presentations becoming very much the “Norm” under the present conditions, the NFPC has invested in multi-webcam systems and the setting up of 5 studio areas from which the Webinars are delivered, making full use of an extensive range supporting visual aids.

John Savage, NFPC Director comments: “We plan to present you with an experience that will complement the requirements of the BFPA (MERs), ensuring that you work safer and have a much better understanding of Fluid Power Systems. From this point onward, you may even consider going to the next stage and obtaining a recognised Competence Based Qualification awarded by the BFPA- Visit our Website for details www.nfpc.co.uk)

For further information please contact John R Savage NFPC Director on jsavage@nfpc.co.uk or Tel No 01909 504709

Powerflow Solutions move to new premises

From Monday 21st September 2020, BFPDA member and Approved Hose Assemblies Scheme member Powerflow Solutions Ltd relocated to new business premises. Their new trading address will be as follows:

Powerflow Solutions Ltd

Unit 3, Brock House

6C Dunnet Way

East Mains Industrial Estate

Broxburn

West Lothian

EH52 5NN

T: 01506 853533

E: sales@powerflowsolutions.co.uk

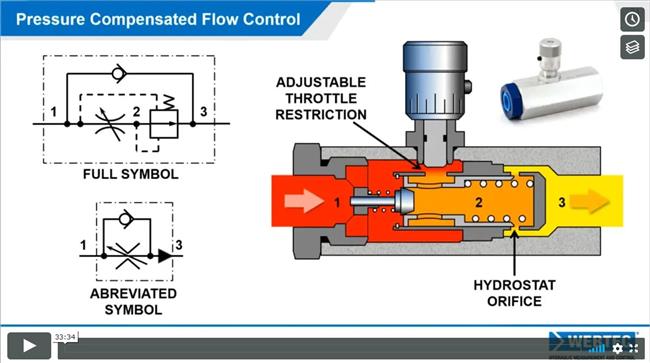

Webtec’s New ‘How To’ Training Video Series Will Strengthen Hydraulic Engineers Skillset

Free-to-view video series presented by industry expert Steve Skinner

Page image from ‘Selecting a Flow Control Valve’ Video

Sharing knowledge and helping to educate engineers in the hydraulics and fluid power industry is important to Webtec. The release of a new series of ‘how to’ training videos aims to cover some of the fundamentals in hydraulics and fluid power to aid engineers at all levels. These free-to-access 30-minute videos join a host of guides and white papers that can be found on the company’s Educational Resource page. Presented by Steve Skinner the key topics covered include:

- Selecting a flow control valve

- Selecting manual directional control valves

- Controlling fluid contamination

More videos are planned for the future which will cover:

- Hydraulic system maintenance

- Hydraulic system troubleshooting

This series of training videos are located on Webtec’s Education page at https://en.webtec.com/education/training-videos/

___________________________

Do you have a company news story we could feature?

BFPA would like to help publicise our BFPA and BFPDA members’ company news (free of charge to members) in our newsletter and / or on our website news page and want to feature more news stories from our BFPA and BFPDA members. Each news item will be set alongside a photo / logo / image (which you would ideally supply) and archived by date. We may also be able to publish on our news pages or send out to a wider media list as well on your behalf.

We would love to hear from you if you have any suitable UK fluid power industry news stories such as:

- Senior staff appointments

- New buildings being opened

- Awards being won / presented

- New industry sales partners announced

- New acquisitions / alliances etc.

- Innovative or unusual projects or case studies

Please send any news items to Sarah Gardner sarah@bfpa.co.uk – we look forward to hearing from you soon!